Products

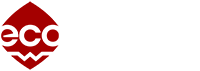

Gas Magnesium Furnace Q Series

Feature

Magnesium alloy gas furnace structural system:

1. The concrete made of special composite steel plate does not pollute the magnesium liquid, has anti-corrosion structure inside, and has long service life.

2. Using natural gas and other heating methods, automatic flame detection, automatic power adjustment, gas automatic gas shutoff protection.

3. The automatic thermal cycle control of the burner improves the gas utilization rate, and the natural gas usage is controlled within 80M3/T.

4. Stainless steel casing and panel, corrosion resistant, high temperature resistant.

5. Imported thermocouple, accurate temperature control and high service life.

Characteristic

1. Insulation furnace over-temperature, leaking furnace automatic alarm.

2. Protection alarm is low, and the protection air flow is low.

3. Automatic flame detection, automatic power regulation, gas automatic shut-off protection.

4. Automatic heat cycle control of the burner, improve gas utilization and save energy.

5. The preheater uses the furnace flue gas to preheat the magnesium ingot without heating the heating element.

6. Alarm and fault information can be traced back.

7. Power supply voltage, operating current LED display.

8. Working status I/O output signal is automatically displayed.

9. Furnace parameter input authorization password control.

10. The backup protection gas is automatically switched.

11. Peripheral device PLC output can be expanded.

12. The status indicator on the control panel of the key work status.

13. Real-time temperature curve visually tracks temperature changes.

14. Temperature data can be exported and process data can be analyzed and saved.

15. The inductive detection function of the bismuth magnesium liquid outlet prevents the empty hammer from being discharged when the pouring pipe is blocked.

16. The quantity and quantity of strontium magnesium ingots are automatically recorded and inquired.

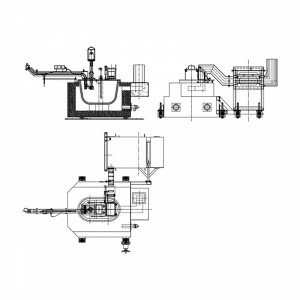

| Gas Magnesium Furnace Q Series Specification List | ||||||||||

| NO | Item | Unit | DMQ-300M | DMQ-600M | DMQ-1000M | DMQ-1500M | DMQ-2000M | DMQ-2500 M | DMQ-3000 M | DMQ-3500 M |

| 1 | Furnace external dimensions | mm | 2000*1550* 1800 | 2500*2050* 2250 | 3430*2260* 2360 | 3900*2300* 2800 | 4500*2300* 3000 | 4600*2800* 3200 | 4800*3200* 3500 | 4950*3400* 3800 |

| 2 | Rated Volume | Kg | 350 | 600 | 1100 | 1500 | 2000 | 2500 | 3000 | 3500 |

| 3 | Melting rate | Kg/h | 150 | 250 | 350 | 500 | 600 | 800 | 1000 | 1200 |

| 4 | Crucible structure | Double room | Three room | |||||||

| 5 | Power | V/Hz/Phase | 380-420V/50-60Hz/Three-phase Five-wire | |||||||

| 6 | Number of burning machines | PCS | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 |

| 7 | Power | Kw | 230 | 230 | 260 | 260 | 300 | 360 | 420 | 420 |

| 8 | Crucible thickness | mm | 24 | 24 | 30 | 30 | 30 | 30 | 36 | 36 |

| 9 | Furnace working temperature(max.) | ºC | 900 | |||||||

| 10 | Magnesium liquid temperature(max.) | ºC | 710 | |||||||

| 11 | provide gas temperature | ºC | 350 | |||||||

| 12 | Transportation temperature | ºC | 680-720 | |||||||

| 13 | quantitative way | Centrifugal | ||||||||

| 14 | Main gas type | SF6/R134a+ N2/Ar | ||||||||

| 15 | (max.)Mix gas flow(max.) | L/min | 10 | 25 | 50 | 50 | 50 | 50 | 50 | 50 |

| 16 | Quantitative range | Kg/s | 0.2~5 | 0.2~5 | 0.5~10 | 0.5~10 | 0.5~50 | 1~50 | 1~50 | 1~50 |

| 17 | Pouring precision | % | ±3 | ±3 | ±3 | ±3 | ±3 | ±3 | ±3 | ±3 |

| 18 | Lifting height of lifting frame | mm | 150 | 150 | 150 | 150 | 250 | 250 | 250 | 250 |

| 19 | Lift moving distance | mm | 700 | 700 | 700 | 800 | 800 | 800 | 800 | 800 |

| 20 | DIN45635-01-K1.2 | dB(A) | <85 | |||||||

| noise | ||||||||||

| 21 | (max.)Preheating machine power | KW | 20 | 30 | 30 | 30 | 60 | 60 | 90 | 90 |

| 22 | Preheating temperature | ºC | 150-250 | |||||||

| 23 | Furnace weight | Kg | 1800 | 2500 | 3600 | 5000 | 6000 | 7500 | 8800 | 9800 |

| 24 | Suitable for die casting machine model | T | ≤500 | ≤800 | ≤1650 | ≤2000 | ≤2000 | ≤3500 | ≤4000 | ≤4500 |